There are many, many different packages of steel strings for banjo (and other instruments) that one can purchase, but the question is: What are the differences among them, and which is the brand/gauge set for you?

(BTW, isn’t it curious that we always speak of string “gauges” but reference their diameters, instead. You’ll recall that gauge numbers go down with increasing diameters, so when we speak of a “ten” we’re really speaking of a string 0.010 inches in diameter. In the American Wire Gauge [AWG] system, that’s a 30 gauge wire. Similarly, a “32,” i.e. 0.032 inch diameter wire is a 20 gauge, AWG. Of no significance, but interesting…)

Basic fact: most, if not all the string manufacturers buy their wire from the Mapes Piano String Company in Elizabethton, TN. Mapes used to have this page on their site:

They recently completely revamped their site, and this page apparently no longer exists, but it’s sort of interesting to see who was (and most likely still is) buying their wire for strings. This implies, of course, that if you buy a 0.010 first string from GHS or D’Addario, or DR, or Ernie Ball, or Gibson, etc. you’re getting exactly the same wire!

They recently completely revamped their site, and this page apparently no longer exists, but it’s sort of interesting to see who was (and most likely still is) buying their wire for strings. This implies, of course, that if you buy a 0.010 first string from GHS or D’Addario, or DR, or Ernie Ball, or Gibson, etc. you’re getting exactly the same wire!

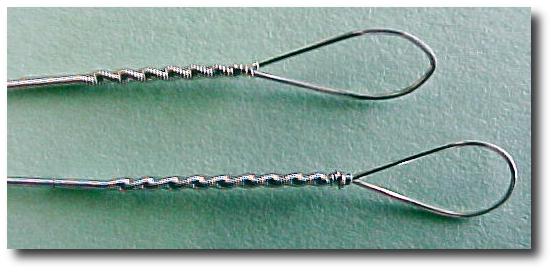

So what is the difference? Different string manufacturers use their own machines to twist loops, wrap the strings or to attach balls to their non-loop end strings. In fact, one can tell some of the different manufacturers’ strings apart by the tightness and number of wraps they use to make their loops. In this photo, the top string was made by D’Addario, the bottom one by GHS:

Likewise, different manufacturers may use different corrosion inhibiting materials, and some cut the strings a bit longer (which can be handy if you have a long neck banjo).

But, in essence, the plain (non-wound) strings are essentially the same wire but in different packages.

The wound strings are a bit different as there are different windings used. GHS primarily wraps with a stainless wire, while D’Addario and most of the others use a nickel steel wire; each also wraps some of its offerings with bronze wire.

Furthermore, when wrapping wire, the tension of a string will be a function of its core, not its windings, which add only mass. Thus, a 0.020W comprising a 0.010 core wound with a 0.005 will have–all other things being equal–lower tension than a 0.020W made of a .012 core wrapped with a 0.004. Some specialty strings take advantage of this difference for marketing purposes.

You’ll note that among Mapes’s customers, there are quite a few other, smaller string brands not listed. Most of these strings are actually manufactured under contract by one those companies that does buy wire from Mapes. GHS- and D’Addario-made strings are labeled and sold bearing many such brands. For marketing purposes, these smaller brands tend to have slightly different gauge sets than those offered for sale by their actual manufacturers.

Other marketing differences involve long-life coatings, e.g. Elixer branded banjo strings have the 4th string coated with Goretex to extend its sonic life. Similarly, Black Diamond offers strings all having a black chemical coating that greatly extends their life. The Ome banjo company still offers chenilled strings (strings with fuzzy wrappings over the loops’ windings).

So my advice to folks trying to decide what strings to buy is this: Banjo strings is banjo strings. So start with the packaging that looks best to you. Then try everything (strings are pretty inexpensive, after all). When you put a set of strings on, save the empty packaging so you can remember what strings they are. If you don’t like their feel or sound or price, try something else. When you find something you like, stay with it.